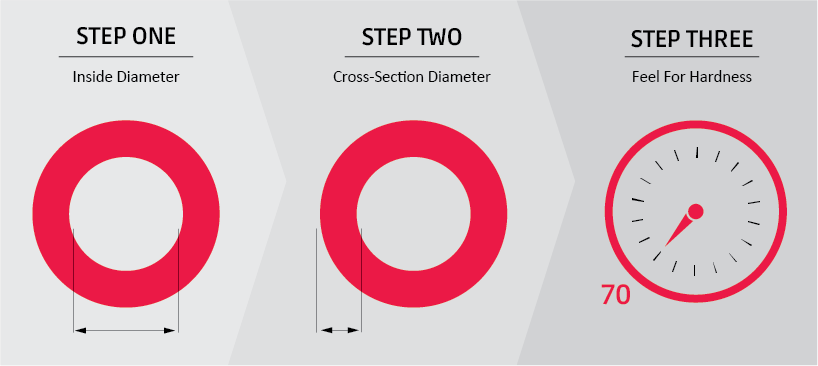

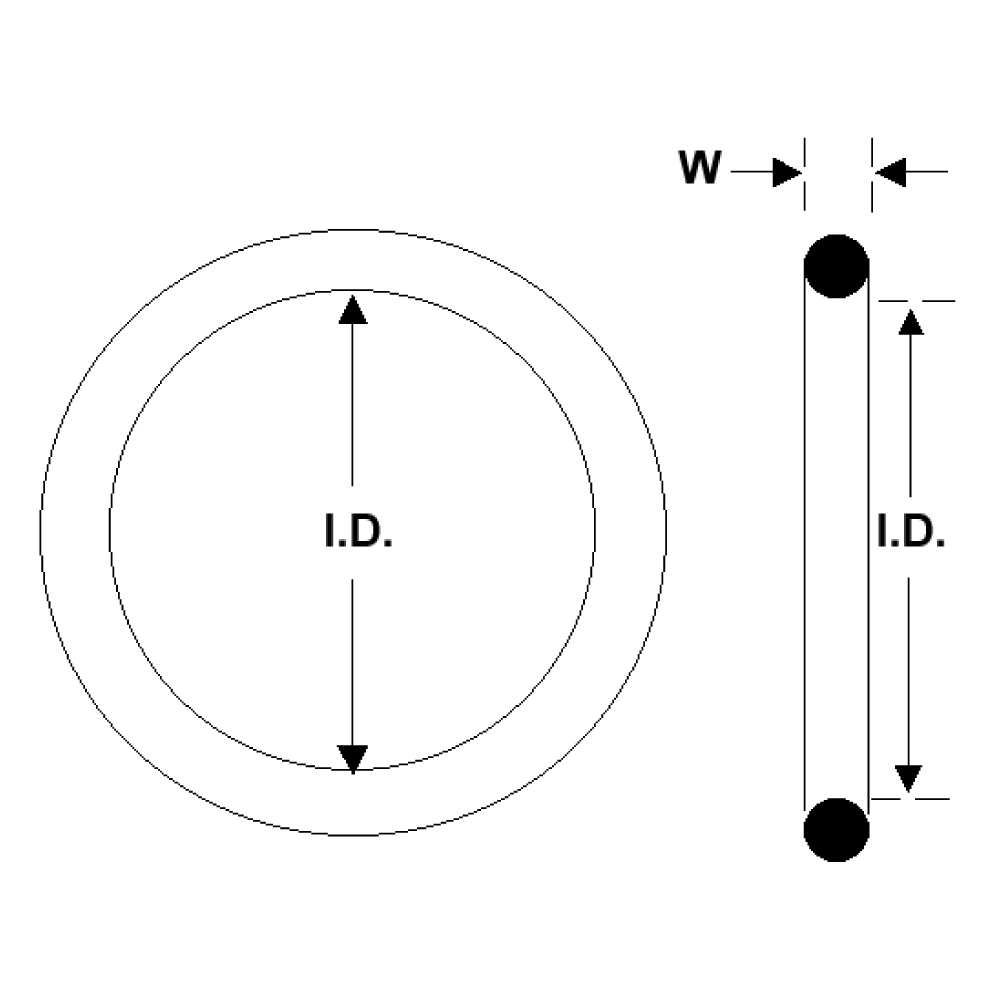

Step 1: Inside Diameter

The ID measures the space between the inner edges of your o-ring. To find this measurement, lay your o-ring on a flat surface. Use a ruler to measure from one inner edge of the o-ring across to the inner edge. Depending on the size of your o-ring, the ID may be recorded in inches or millimeters. This will help determine how large of an opening your seal should have.

Step 2: Cross-Section

The CS of your o-ring is otherwise known as the width or thickness of the seal. To measure the CS, you will likely need a vernier caliper. Place the o-ring in the caliper lightly, without compressing it. Measure and record the width of the rubber. This is an important measurement, as the width of the seal plays a major role in a seal’s compression resistance, volume swell and abrasion resistance.

Step 3: Feel for Hardness

Every rubber material has a unique hardness, which is measured by the Shore A durometer scale. A general rule of thumb is the harder the compound, the higher the durometer. Standard rubber compounds generally have 70 Shore A hardness, but hardness can vary based on the material and the application. 70 shore A hardness o-rings cover all automotive intended applications.